Check valve manufacturers in Germany

Valvesonly Europe one of leading Check valve manufacturers in Germany offers high-quality check valves for commercial applications. Check valves, also known as non-return valves (NRVs), are vital parts of hydraulic systems that allow one-way flow and stop backflow.

An automatic check valve eliminates the need for manual operation. Pumps, pipes, and other equipment will be harmed because it allows unhindered flow in one direction while prohibiting movement in another.

What is a Swing Check Valve?

When liquid moves in the intended direction, a swing check valve’s hinged disc swings open; when movement is either absent or changed, the disc seals. The swing action is suitable for applications needing a small pressure drop due to its low flow resistance. Swing check valves are frequently found in gas, oil, and water pipelines because of their simplicity of construction and efficient operation.

Advantages:

Prevents Backflow: Guards pipes and pumps from damage caused by reverse flow. Automatic Operation: Requires neither physical labour nor external power. Low Maintenance: the body is small, light, and has few working elements to reduce friction. Rapid Response Time: When there is backflow, it closes immediately. Energy-efficient: Reduces the need for additional flow control equipment.

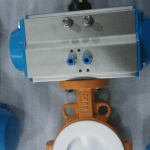

Check valve types:

Swing check valve Ball check valve Lift check valve Dual plate check valve Silent check valve Non slam swing check valve Tilting disc check valve Pressure seal check valve Foot Check valve Piston check valve

Check Valve Industries:

Chemical Industry Pulp and paper Industry Marine Industry Mining Industry Power Generation Industry Oil and Gas Industry Nuclear Industry Petrochemical Industry Water Treatment Plants Textile Manufacturing Industry

Check valve manufacturers in Germany is widely recognized in the industrial sector for its smoothness and easy reach.

Description:

Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

Size- ½” – 80” Class-150 – 2500; PN10 – PN-450 Ends- Threaded, socket weld, butt weld, flanged, lug, wafer