The Future of Surface Restoration: How Laser Technology is Changing the Game

In the world of industrial maintenance, restoration, and manufacturing, surface preparation has always played a critical role. Whether it’s removing rust, paint, or contaminants, companies across sectors need reliable, safe, and efficient methods. Traditional techniques like sandblasting, chemical stripping, or grinding have long been the go-to, but they come with limitations—abrasion, residue, toxicity, and environmental hazards.

Enter the age of laser technology—a precise, powerful, and cleaner alternative that’s revolutionizing how surfaces are treated. At the forefront of this shift is Alfa Laser, a company committed to innovation, quality, and high-performance solutions.

The Shift Toward Smarter Cleaning Methods

Industries are moving away from outdated, aggressive methods that can damage surfaces or pose health risks to workers. Laser cleaning brings a non-contact, non-abrasive method to the table, making it ideal for intricate surfaces and sensitive materials. It doesn’t rely on chemicals, high-pressure blasts, or manual scrubbing.

Instead, it uses a highly focused beam of light that vaporizes contaminants like rust, oil, paint, and corrosion without affecting the underlying surface. This makes laser cleaning the top choice for industries such as automotive, aerospace, marine, construction, and even heritage conservation.

Why the Laser Rust Stripper is a Game-Changer

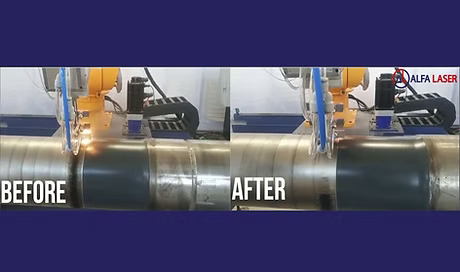

One of the most impressive applications of this technology is the laser rust stripper. Rust has always been a stubborn enemy—especially for metals exposed to moisture, salt, or harsh environments. While mechanical rust removal tools can work, they often leave scratches or uneven finishes.

The laser rust stripper delivers a uniform and precise cleaning process. It removes rust layer by layer without harming the metal beneath. This is particularly valuable in automotive restoration, aerospace maintenance, and structural preservation, where material integrity is vital.

Another huge advantage is safety. There are no abrasive materials flying around, no toxic dust clouds, and no harsh chemicals to handle. It’s safe for workers, safe for the environment, and effective on even the most delicate surfaces.

The Science Behind Laser Clean Technology

What makes laser clean so effective is the controlled energy of the laser beam. It targets only the contaminants on the surface—like oil, soot, paint, and corrosion. As the laser energy hits these materials, they absorb the light and heat up instantly, causing them to either evaporate or disintegrate. The substrate beneath remains unaffected because it reflects the laser’s wavelength.

This precision is unmatched in traditional methods. For example, when cleaning mold tools or welding surfaces, precision is everything. A poorly cleaned surface can lead to poor welds or defects in molded products. Laser cleaning ensures perfect prep work every time, with no residues left behind.

Cost Efficiency Over Time

While laser machines might seem like a bigger upfront investment, the long-term savings are substantial. Think about it—there’s no need to buy sand, chemicals, brushes, or protective gear constantly. You don’t have to spend hours on cleanup or disposal of hazardous waste. And because laser machines are durable and low-maintenance, their operational costs remain minimal.

For many industries, time is money. Laser cleaning significantly reduces the time spent on surface prep, allowing for faster turnaround and improved productivity. Over a year or two, businesses easily recoup their investment while enjoying cleaner, safer work environments.

Environmentally Friendly Cleaning Solution

In today’s eco-conscious world, companies are under increasing pressure to adopt greener practices. Many traditional surface cleaning methods rely heavily on chemicals that harm the planet and leave toxic waste. Laser cleaning is completely chemical-free. It produces no solvents, no effluent, and very little dust or debris. That makes it ideal for operations that value sustainability and want to reduce their environmental impact.

Additionally, since it doesn’t generate waste material, there’s no need for special disposal methods. You’re not just protecting your workers—you’re protecting the planet too.

Portable and Versatile

Alfa Laser offers models that are not just powerful but also compact and portable. This flexibility means you can bring the cleaning tool to the job rather than moving large or heavy parts to a dedicated cleaning station. Whether you’re cleaning rust off ship hulls, removing graffiti from public spaces, or restoring historical artifacts, portability is a huge plus.

These machines can also be customized for automation. If you’re running a high-volume production line, you can integrate laser cleaning seamlessly into your workflow. That’s future-ready technology made accessible today.

A Wide Range of Applications

The industries that benefit from laser cleaning are growing by the day. Just a few examples include:

Automotive: Rust removal, mold cleaning, engine block prep

Aerospace: Paint stripping, corrosion cleaning, component degreasing

Construction: Surface prep for welding, concrete mold cleaning

Maritime: Ship deck and hull cleaning, rust and barnacle removal

Manufacturing: Tool cleaning, parts prep, product finishing

Cultural heritage: Restoring historical artifacts without damage

Each use case benefits from the precision, safety, and sustainability of laser technology.

Alfa Laser: Pioneering the Future of Surface Technology

At Alfa Laser, it’s not just about selling a product. It’s about offering a reliable solution. Each machine is engineered for performance, built to last, and backed by a team that understands your industry challenges.

Whether you’re a workshop owner needing a reliable way to clean parts or an industrial plant manager looking to modernize your operations, Alfa Laser’s solutions are tailored to meet your needs. With training, service, and tech support, you’re never alone on your journey to innovation.

Their portfolio includes handheld units, mid-size models, and large-scale systems that can be integrated into robotic lines. Each product is tested for quality and built to deliver exceptional results every time.

Looking Ahead

Technology is evolving fast, and industries need to keep pace. Laser cleaning isn’t just a trend—it’s the new standard. As regulations tighten and competition grows, those who invest in safer, smarter, and more sustainable solutions will come out ahead.

Choosing Alfa Laser means choosing a partner committed to excellence. With unmatched expertise, cutting-edge tools, and a dedication to customer success, Alfa Laser is lighting the way for a cleaner, greener, and more efficient future.

Conclusion

The rise of laser technology is transforming surface treatment, and the benefits are hard to ignore. From the highly effective laser rust stripper to versatile, eco-friendly laser clean applications, industries now have access to a cleaning solution that checks every box—efficiency, precision, safety, and sustainability.

Alfa Laser’s commitment to quality and innovation makes it a trusted partner for businesses ready to upgrade their operations. If you’re looking for a future-proof cleaning solution that delivers outstanding results without compromise, laser technology is the answer—and Alfa Laser is your gateway.